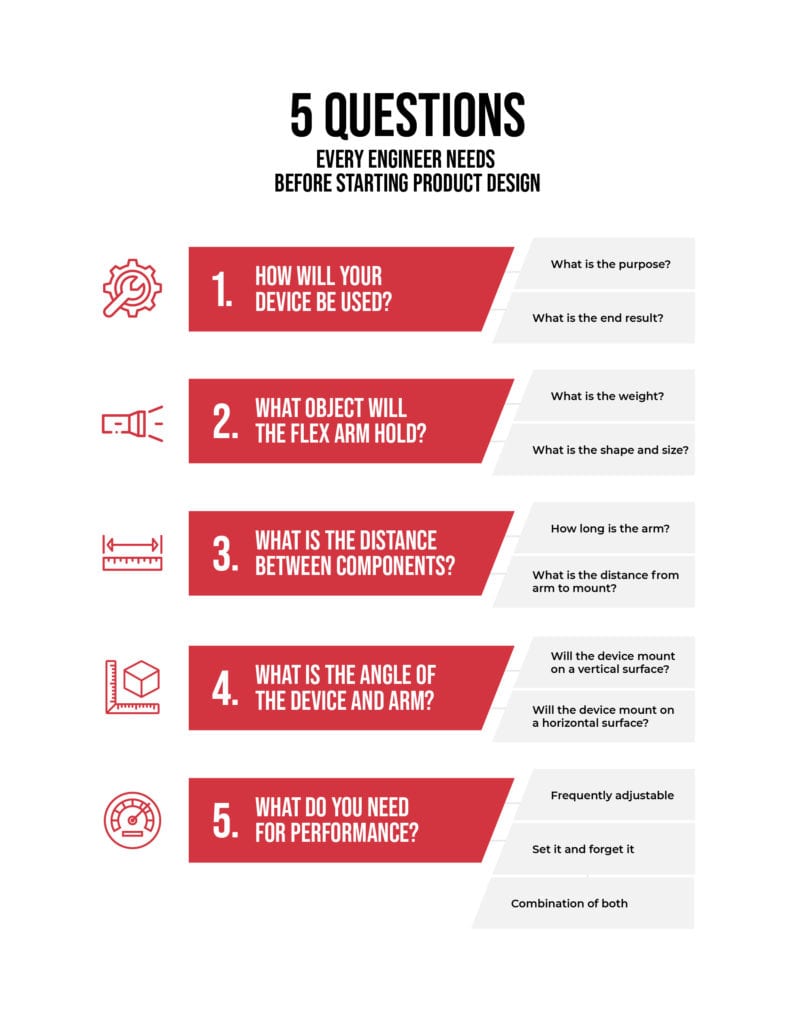

5 Questions Every Engineer Needs Before Starting Product Design [INFOGRAPHIC]

Share:

Beginning a product design can be overwhelming. It can be a lot of pressure if you don’t know what you don’t know. Every product is a little different and there are always aspects you can customize along the way to fit your specific needs. But if you’re just starting a product design, these are the five questions you should be asking yourself before committing to any one solution.

1. How will your device be used?

Ask yourself what the purpose of your device is. Who will be using it and in what environments? What is the end result after someone uses the device? What is the need and how are you solving it with your product? A good way to start thinking about this is to put yourself in your end user’s shoes and write down the key components that will make their life easier when they use your device. These are the first questions that need to be answered before deciding on the specifications of your flex arm device.

2. What Object Will the Flex Arm Hold?

Think about what the flex arm will be holding in your product design. What is the weight of that object? How will the shape and size of the object impact how it is held? What material will be used for the object the flex arm holds? When we work with our customers on a custom product design, we send samples so that you can start to see and feel what your device may be like.

3. What is the Distance Between Components?

Some devices need a longer flex arm due to how the device will be used in context. Some of our customers use devices in the OR where the flex arm needs to be long enough to support a variety of different surgeries and provide light in a number of scenarios. Other devices require a shorter flex arm for increased stability. How long does your flex arm need to be? What is the distance from the arm to the object it holds as well as the distance between the arm and the mount? Start taking some measurements so we can develop a prototype.

4. What is the Angle of the Device and Arm?

Think about the surface that your device will be attaching to. What is the angle of that surface? Will your device be mounting to a vertical angle, such as a part of the wall? Or will it be adhering to a horizontal surface such as a table? This will influence what type of mount you choose as well as how the object connects to the flex arm.

5. What do You Need for Performance?

Once you have the basic questions answered, you need to start thinking about what kind of additional performance you need in your product design. How frequently will you be adjusting your device? Are you a woodworker who needs your flex arm to stay in place for hours at a time as you perfect the details of a piece of furniture? Or are you moving your device constantly to give you different angles every few minutes? Other factors to consider are what type of environment your device will be used in and if it will be harsh and high use or more mild.

———————

Ready to start your product design? We will work with you to develop a product that fits all your specifications. We’ve developed everything from medical devices to industrial machines to tactical cameras. We guarantee we can create a solution that works for you. Check out our device development page to see how we can help you.