Custom Flex Arm Components vs Engineered Components: What’s the Difference?

Share:

Let’s say you have a great idea for a medical device and you think a custom flex arm component might be needed. You shop around, find one you like, work with your supplier then realize: you’re going to need an engineered solution for your end fitting. Will it be too expensive? How is a custom part different from an engineered part? Is there a better option?

The difference between a custom flex arm component and an engineered one

Before we start, let’s nail the terminology down so there isn’t any confusion: When we say custom, we simply mean non-standard or unique from any other designs we have. There might be a previous design that has 95% of the parts you need, and we need to substitute just one part to make it custom for you.

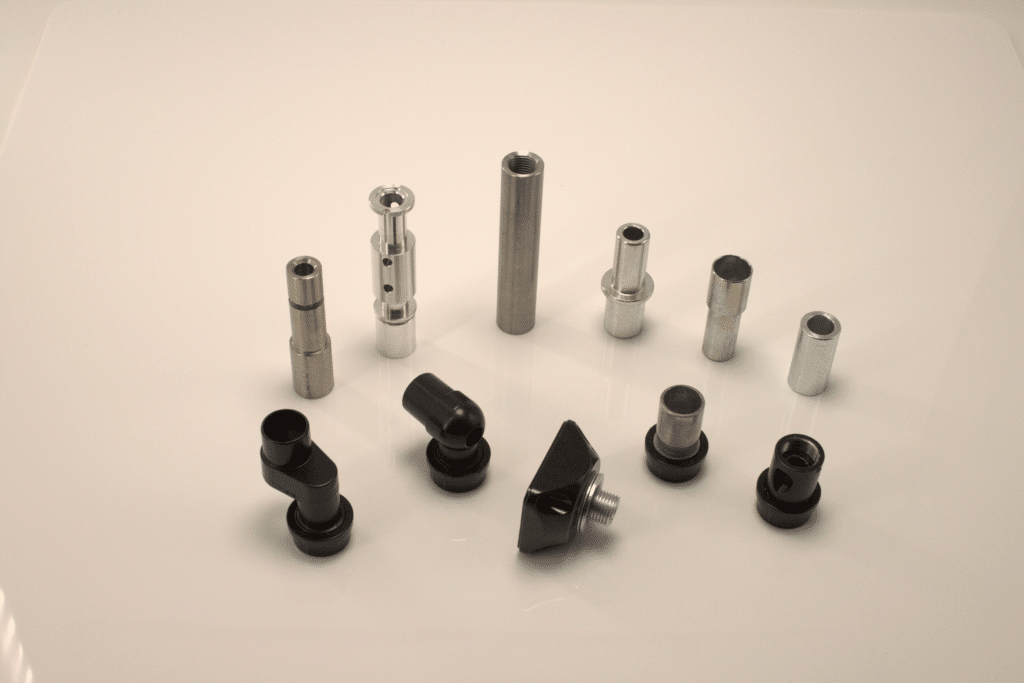

Often times we are able to use a component we created for another customer. If there’s nothing proprietary about it, and it works for your project, that’s an easy match to make! We’ll use the same part in multiple places and everyone wins.

An engineered part is something that we will have to create from scratch or modify an existing part specifically to work with your device. It means that time, energy, and thought will have to go into creating a solution.

At what inflection point is an engineered flex arm component worth it?

In the simplest terms, the larger your order, the more it will make sense to utilize an engineered flex arm component option. If you’re going to order 500 or 1,000 pieces from us then it’s probably not a problem for you to have an engineered flex arm component. If you’re ordering less than that – say 50, then it’s probably a little more prohibitive.

How often do our customers need a custom flex arm or engineered component?

It might surprise you to hear this, but most of our products don’t need a custom flex arm or engineered component. The vast majority of the time we have a component that already works. The even better news? That number continues to go up as we work with new and exciting clients. It’s sort of the natural cycle of our components. Something that was once engineered becomes custom, and may eventually become a standard component.

The biggest obstacle to overcome isn’t money. It’s time. Here’s how much time it takes to make an engineered part

For us, the biggest obstacle we see our clients face with engineered components isn’t a money issue – it’s a time issue. If we can utilize something we’ve already engineered then often it may only be a matter of weeks for a turnaround time. On the other hand, if we’re going to need something engineered specifically for your device it could be months before that component is ready.

That’s why we encourage healthy collaboration and conversation with our clients. When we know what you’re looking for, we can offer solutions that work within your budget and on your timetable. As you know, that’s a big deal when you have a hard launch for a product. You want to know that your components will be available in a timely manner with the utmost care taken to ensure their quality.

Are you ready to have that conversation? Drop us a line, we’d love to discuss your next device.