Good Flex Arm Vs Bad Flex Arm: Is there actually a difference?

Share:

We don’t take lightly the trust that our clients put in us to build a good flex arm. Why? Because we know how hard it can be to find a good supplier — you want to get it right for your device. We’ve been blessed with many great partners and suppliers, but only because we knew what we were looking for — and had partners in the industry who were on the same page.

If only it were that easy for your flex arm device. It can be hard to evaluate a flex arm (or the company that makes it). What if there was a way for you to understand the difference between good and bad? The good news? You can. We’re here to help you. From understanding how coverings might affect your flex arm to how to talk about the process, here’s what we look for when we’re evaluating a potential flex arm company

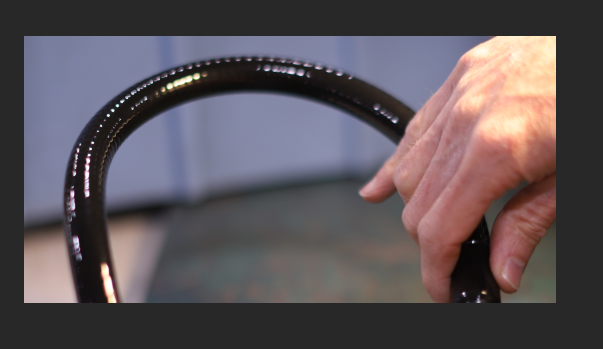

Is it a good flex arm? Looks can be deceiving (check the covering material)

One of the easiest ways to spot a flex arm that might not be up to snuff is to look at the covering material used. While aesthetics are important, performance will always be essential. While the process of making a flex arm is mostly the same across the board, the use of poor covering can dramatically affect the performance and life cycle of your flex arm device.

We call these contradictory covering materials. That can include paint, cheap plating, or basically anything that reduces friction. This is the enemy of the flex arm because, at its core, a flex arm is a friction-based product. We don’t like when we lose it because that causes surprises (like lessening the lifespan of your flex arm device). We want to know and control how the covering affects the flex arm. That’s the only way we can meaningfully predict how that arm will perform in the field. In short, that’s how you make sure it’s a good flex arm.

Often the process will be the same. Here’s how to tell which is best.

Look, the basic process for building a flex arm has been around for a long time. It’s not always apparent whether a flex arm will be high quality or low quality. That’s only revealed after talking with the folks who make the flex arms. Here are some questions you’ll want to ask of any potential flex arm company.

- What coiling materials do you use? For us, we’ll often use a standard material if cost is the number one issue (like many other companies). But if precision and performance are key for a good flex arm, we may use brass, stainless steel, or other premium materials. If a company is giving you those options, it means that they’re thinking about quality.

- How does our device’s application affect your process? When we work with a new client, the application determines everything — from the materials to the winding. Angel Eye Cameras are a great example of this work. If a company already has a pre-fab plan where they just shoehorn what they have into your design, then they’re probably more concerned about the sale than the device.

- How will you match our aesthetic? As previously mentioned, this is a big one for understanding their end process. If they’re using paint or other contradictory covering materials, it may mean that they’re cutting corners.

Car or flex arm, it’s important to take it for a test drive

To be honest, the best way to understand if it’s a good flex arm is to see it in person. You’re going to want to manipulate it in the ways your device will need, play around with options, and see what any potential flex arm supplier has to say about how it fits into your design process.

Tons of companies manufacture cars, but it’s only after you test drive one that you can truly understand why it’s right for you. That’s precisely why we encourage folks to contact us to send them a prototype and talk through their design needs. When you get a good demo, you know. The sales team doesn’t have to say much because the product speaks for itself. Now THAT is a good flex arm.

_____________________

Are you working on a flex arm design? We are here for a no-pressure phone call. We’d love to hear more about what you are working on and give you ideas and prototypes to improve your decision-making process. Give us a call; we promise it will be worth your while.