Be Nimble: How HatchMed is Changing the Game for Patient Care One Device at a Time

Share:

Med Tech is an exciting field where breakthroughs in technology happen nearly every single day. That’s exactly where HatchMed stands: at the very forefront of patient care. We had a great conversation with the team at HatchMed, a medical device manufacturer who works with Moffatt, to understand the challenges they face, how they created some of their most iconic and successful products – and what it was like to work with us (we had to ask!)

Hospitals are a battlefield

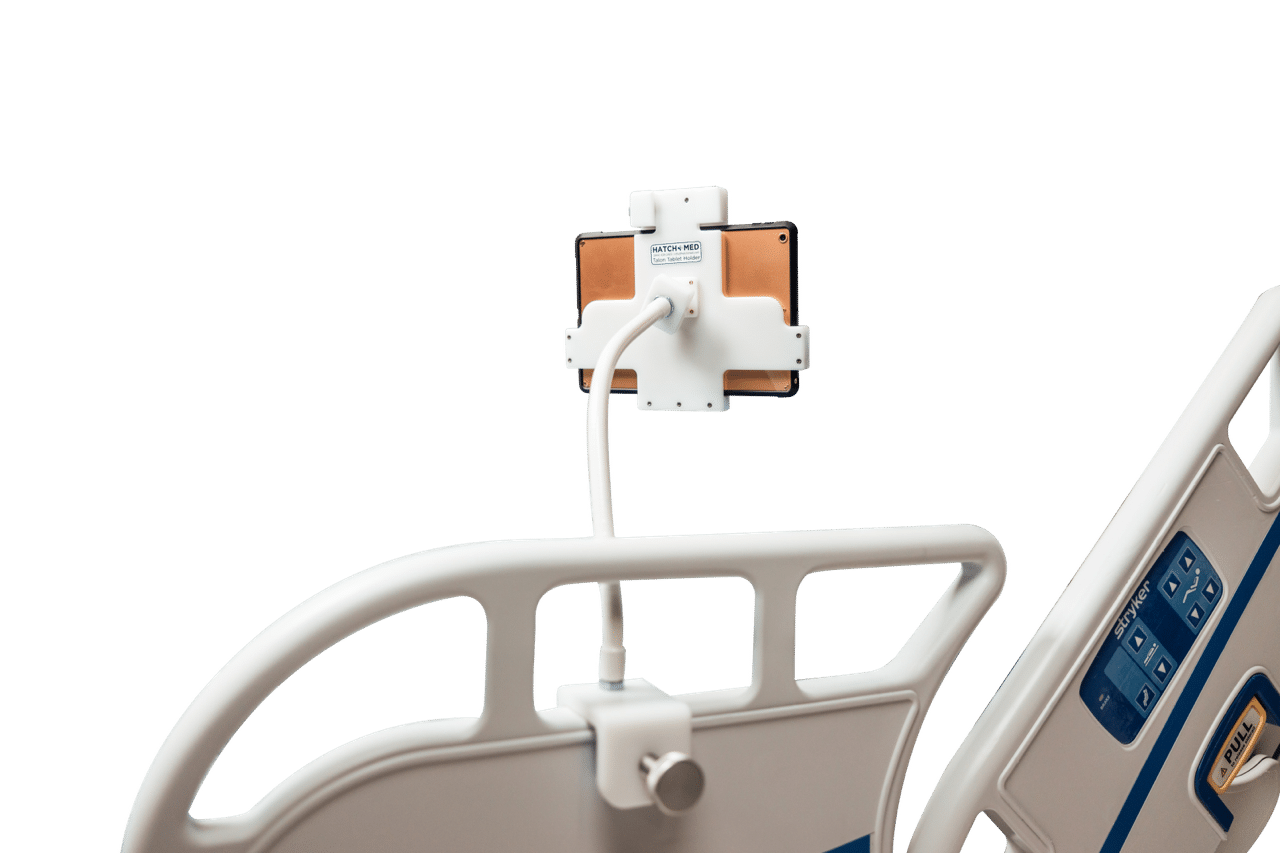

One of HatchMed’s most successful devices in 2020 was their Talon tablet holder. It’s an elegantly designed device that allows patients to have a table or wall-mounted option for use with any number of different tablets. These have been instrumental to patient care, especially as the COVID 19 pandemic has shown the need for remote communication with loved ones. Brian Hatch doesn’t sugarcoat why his devices need to be durable.

“The patient room is a battlefield. We have a product that needs to be able to withstand those rigors – which means that we need to make sure our suppliers understand those demands,” he said. “On top of that, there’s a lot to consider. This is a universal product that needs to fit tablets but also universally fits hospital beds. Because there are so many beds and types of structures out there, these combinations can be kind of tricky.”

How HatchMed began working with Moffatt to create a better, more durable flex arm device

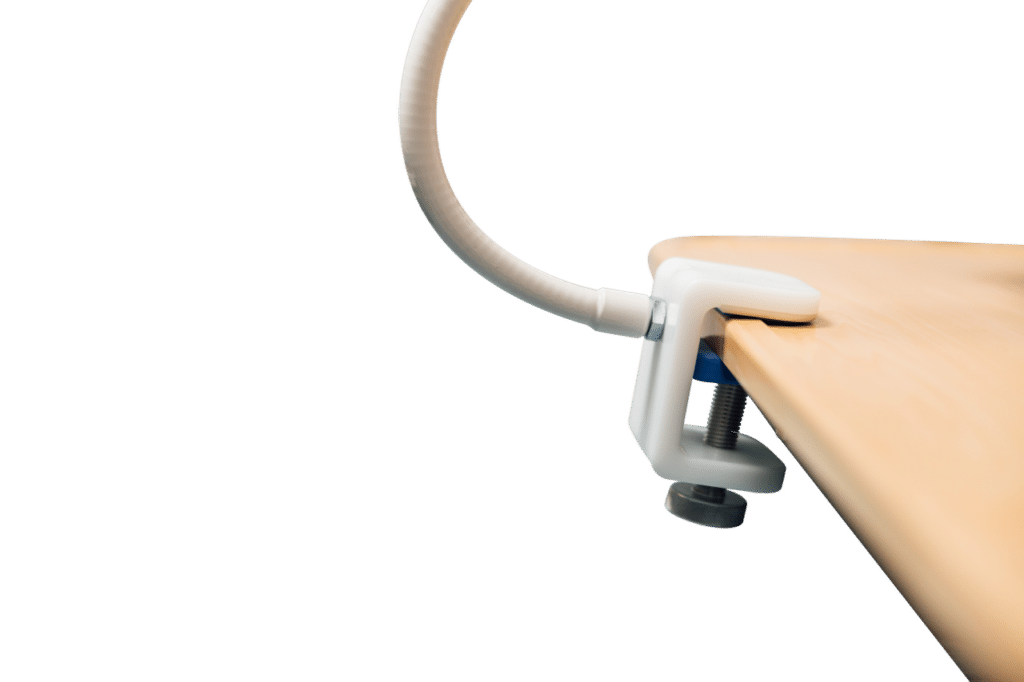

When HatchMed first created their tablet holder, they went through several options for arms, including a static one with ball joints. Unfortunately, that option had a lot of cracks and creases in it that just isn’t conducive to the hospital atmosphere – which puts a lot of pressure on its devices to hold up to repeated use and regular cleanings.

During the development phase, Hatch spent a lot of time in hospitals. While there, he started to notice a component on other medical devices that he thought might fit their needs as well. “I started seeing flex arms everywhere,” said Hatch. “I saw them on hospital beds, on the NICU carts. I realized that this could be an option for us, so we got some samples.”

The Moffatt arm meets the HatchMed mount

“I started seeing flex arms everywhere,” said Hatch. “I saw them on hospital beds, on the NICU carts. I realized that this could be an option for us, so we got some samples.”

After meeting Moffatt at a trade show, HatchMed requested several options for their device.

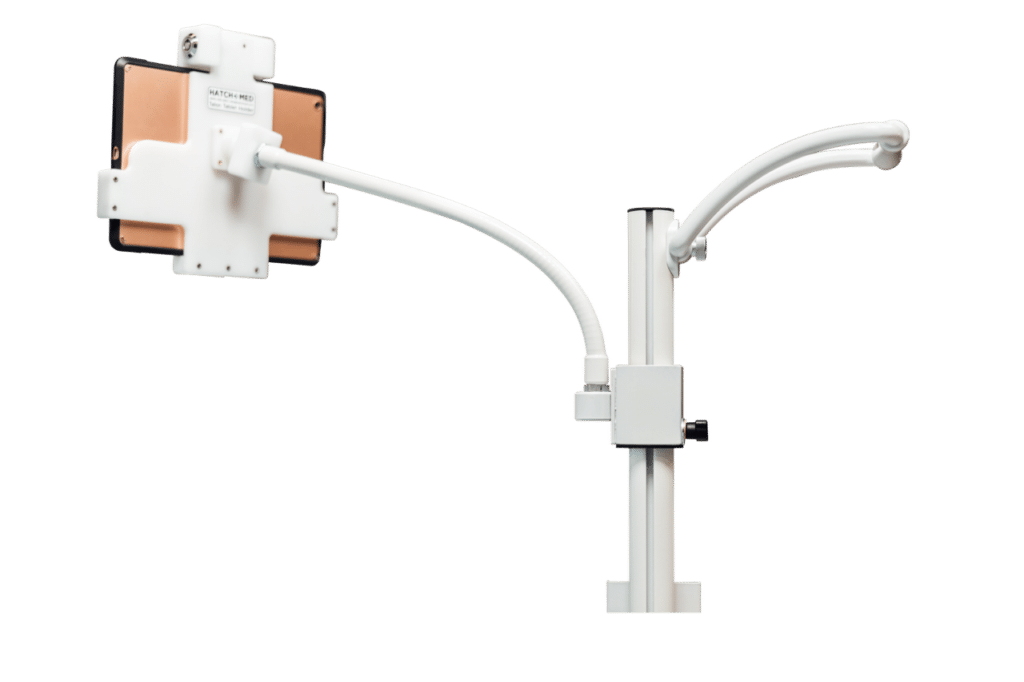

Those samples were important because they demonstrated two key components: reach and stability. Hatch was drawn to Moffatt’s arms because they allowed them the stability to hold a tablet but were able to meet their aesthetic needs as well. Through work with Moffatt, HatchMed landed on a 16” gloss white flex arm during the R&D process. This became part of HatchMed’s signature device, The Bed Talon

“It’s sort of right in that sweet spot. We found the perfect stiffness of arm for us, which is strong enough for basically any tablet – but at the same time, you can still move it around without actually yanking the clamp off the rail… Even if you have a tablet on it, you can almost put it horizontally… That was a big thing that we were trying to solve: eliminate drift, but still being able to position it in front of the patient,” said Hatch.

All this while still being lightweight and maneuverable enough that it is easy to move around and mount to carts. As HatchMed has grown, they’ve created more accessories, height adjustments, and several other design features – in the end, though, it always comes back to the Bed Talon.

“That’s our bread and butter and what we started with.”

The future of HatchMed and the challenges we face together

Even though the talon is an excellent product, HatchMed isn’t resting on its laurels. With several different lines of devices in hospitals right now, they’re already looking to the next phase for their company – and the challenges they’ll have to face to get there.

“In five years, we want to be a leader in connecting bedside technology to patients in hospitals,” said Hatch.

That means challenges for Moffatt as well. One big goal of HatchMed is to have a flex arm that is still robust but can support a lightning cable running through it. As we continue to work with them, it’s a challenge that we at Moffatt are excited to tackle. We have a creative team of people who can prototype most things they need – not just flex arms but other components as well.

We love working with HatchMed because they value the same things we do. It’s been a joy to bounce ideas back and forth, and we love being able to work with their team because it helps us get out of our comfort zone and think outside the box.

We’re excited to see what the future holds for HatchMed. We know they are too.