Does a flex arm have to be permanently mounted?

Share:

You have the possibility of many different mounting solutions for your next medical device. What makes a flex arm special? You have options when it comes to how that flex arm is mounted to your device. In fact, from permanent mounts to c-clamps, each has its own benefits depending on the situation you need. Here is a quick rundown of just SOME of the options we have created for our flex arm devices. Don’t see an option that you’re looking for? We bet we can help. Email us and ask! We’d be happy to make your design dream into a reality.

Why we’ve created so many mounting options for flex arms

Typically, when we work on a mobile medical device, we want to have the gooseneck as close to the user as possible. That’s because reach is ultimately more challenging for a gooseneck than other jointed assemblies. That means you’ll want to pull the mount right up to the bed (or wherever it’s needed).

The problem is – and we are sure you’re aware of this – that there is such a variety of hospital beds and handrails that it can be tricky for us to design something that accommodates ALL the varieties. That’s why you want a partner who can work with you to create specific designs that will match up with the hospital room that WILL house your device – not a hypothetical one.

A permanent mount is an option, but it’s far from the only option

We aren’t salesmen; we’re engineers. We don’t just want to package one of our existing products to you and “market” it as a solution. Instead, we’re dedicated to ensuring that we FIND the solution first, THEN go with the fitting that makes the most sense to accomplish that goal. We also understand that there is such limited space in a hospital room that your product needs to have maximum impact with as small of a footprint as possible.

We frequently create direct mounts for our clients; integrating into their existing product through engineering, color matching, and our regular design process. Though it’s a common option, it’s far from your only one. Let’s look at a few others that some of our clients have used in the past.

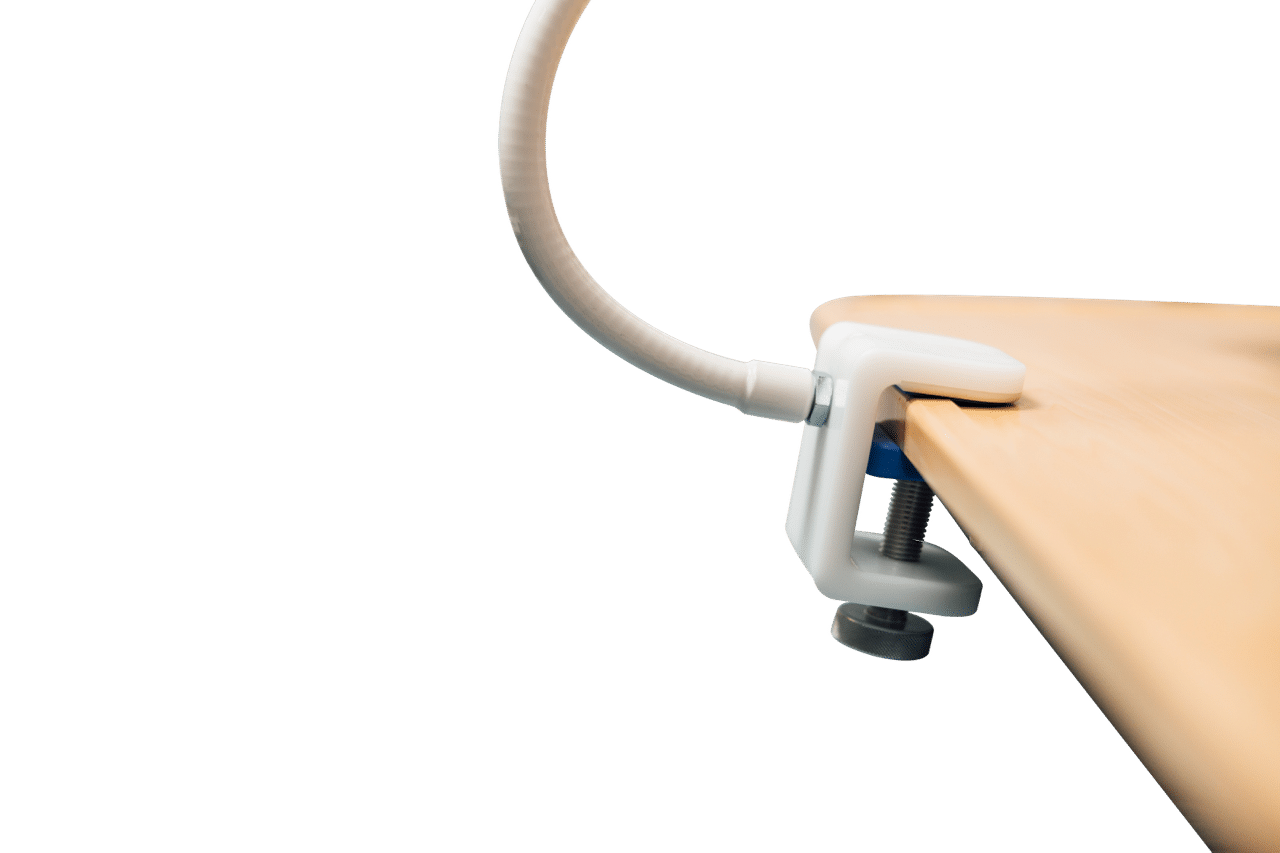

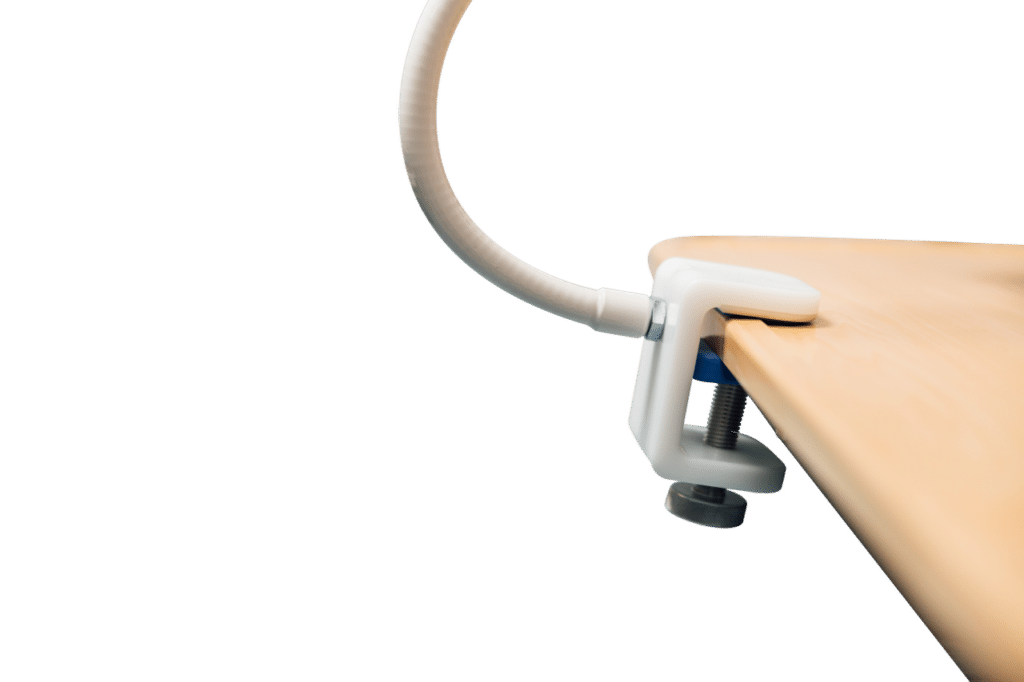

A C-clamp provides stability for square profiles

We use C-clamps often for these projects – because they work. Our C-clamp works with square profiles, which ultimately seems to work very well with most of our mobile devices. It allows you to remount a device to wherever is most advantageous. It does need a square profile (not rounded) to be able to do its job effectively. That said, we always prioritize what the customer wants – and so if something on your device is more akin to a round profile, we’re confident we can engineer a solution to make it work.

Flex arm mounts can integrate into existing headwall systems for more support

Our background is in lamps, and often that’s where our customers want the most help – in shining light in a hospital setting. We’ve mounted exam lights to chairs, stationary on a wall,beds, or tables. Most of these designs incorporate the flex arm to be designed right into the device, permanently mounted for the greatest support for their device.

Headwall systems are extremely important to hospitals because they coordinate so many disparate tools to be used for patient health. We’ve worked with many companies, including GCX, to create mounts for headwall systems. While GCX is a great example of what we do, it’s far from the only example. We’re constantly working on more headwall systems, so if your device needs a different setup, we will encourage you to reach out and ask.

Quick Couplers can offer the best of both worlds

A quick coupler can offer a great amount of flexibility in terms of both the options it gives you for mounting while also allowing for greater stability. In some cases, say if your flex arm might need to be cleaned, it’s easiest to have a removable component from your device. A quick coupler allows for that possibility with just a snap.

Do you have questions about your next project? Let’s talk.

As always, to find a great solution you need to understand the problem first. In our experience, that’s what we do best. Think of us as an extension of your design team – one that has decades of experience in this specific component. If you have a big idea but need someone to help you flesh out the details of how to integrate a flex arm component (or related end-fittings, integrating lightning cables, etc), then we encourage you to reach out to us. Let’s work through it together and make something great.