How to Decide Which End Fitting You’ll Need for Your Flex arm Device

Share:

Flexible arms are easy to adjust and stay in place, but just as important are the end fittings for your flex arm device. End fittings provide mounting features that the flex arm alone can’t achieve, and can help make motions that allow the device to be easier to use. Rotation at one or both ends allows the user to position their arm in the desired shape, then swing the device in and out of position while reducing the demand and wear on the flex arm.

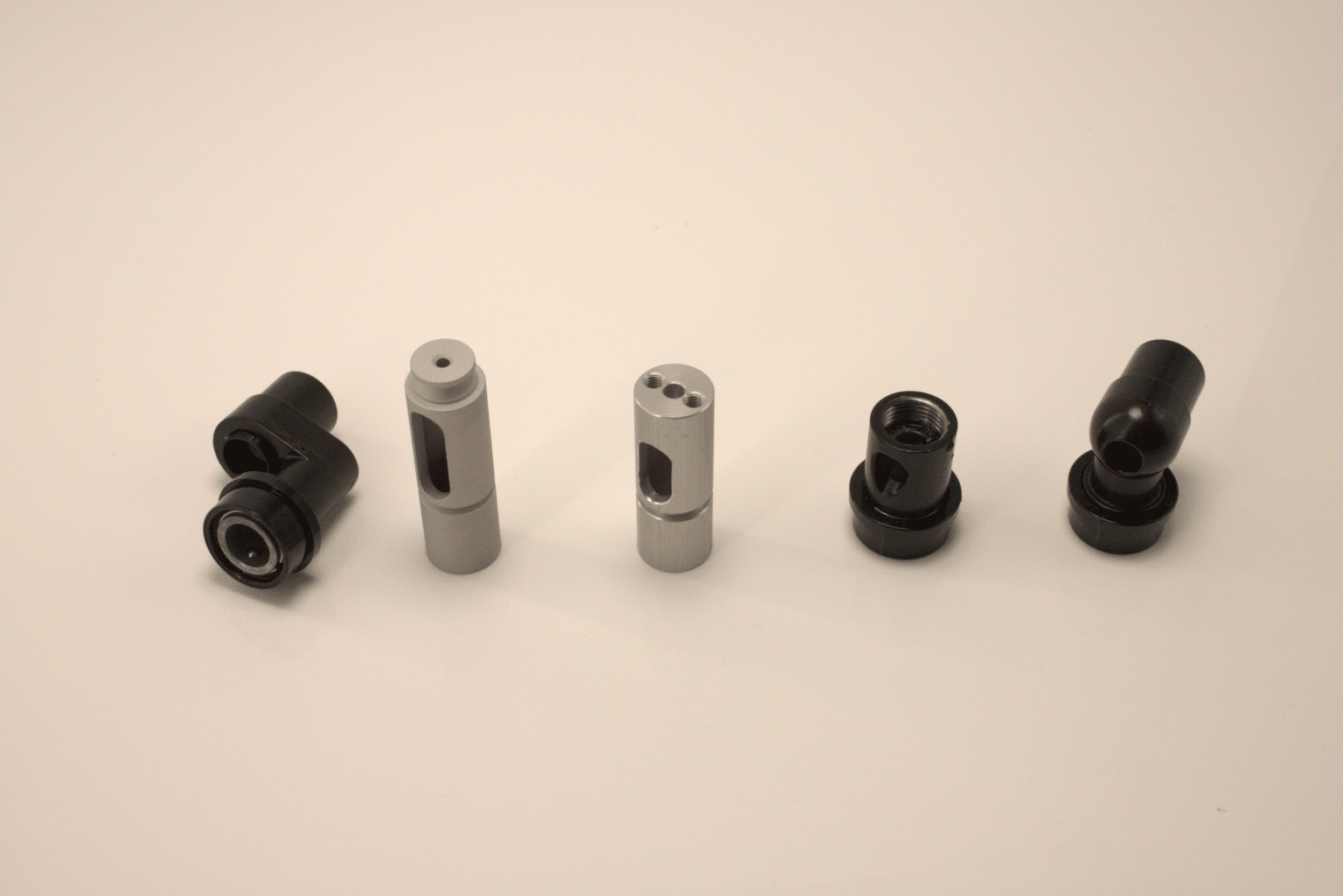

Here are some of the types of end fittings that we provide – and how they might impact your next flex arm device

Flex arm end fitting: ball swivels and cable management

A ball swivel works great for positioning devices with screens. They come with a tension adjustment knob so that the ball swivel can hold a specific position firmly. These are also able to be paired with cable management features if data or power cables are required – something that is fairly common with many of the medical devices we help create.

Cables can be routed inside the arm, exiting straight through the ends – or through mouse holes that go through the sidewall of the end fittings.

Flex arm end fitting: Threaded fittings, c-clamps, and quick disconnect couplers

For folks who need an economical solution, threaded fittings can be a great answer to their end fitting needs. Threaded fittings are the least expensive to produce and connect with mating parts or various types of hardware. C-clamps and quick disconnect couplers can make the assembly more versatile or mobile. Accessory kits provide additional mounting options for those types of fittings.

What to look for: Prototyping after selecting and designing end fittings

The correct end fittings will provide the right motion and mounting features, which makes for a user-friendly experience. It will also make them more reliable and keep the position your device needs. When you hop on a call with us, the Moffatt team will ask you some questions so we can help you understand the project scope, timeline, and concept. You’ll show us what features the end-user is going to expect, then we’ll select or design the right end fittings to match so that a prototype arm assembly can be shared with you and your team. In our experience, it’s easier to make those decisions when you have physical parts in your hands. That’s why we focus on completing these early steps quickly. Once the end fittings pass your inspection, we can move forward with a good representative of your flex arm device.

For us, the biggest obstacle we see our clients face with engineered components isn’t a money issue – it’s a time issue. If we can utilize something we’ve already engineered then often it may only be a matter of weeks for a turnaround time. On the other hand, if we’re going to need something engineered specifically for your device it could be months before that component is ready.

That’s why we encourage healthy collaboration and conversation with our clients. When we know what you’re looking for, we can offer solutions that work within your budget and on your timetable. As you know, that’s a big deal when you have a hard launch for a product. You want to know that your components will be available in a timely manner with the utmost care taken to ensure their quality.

Are you ready to have that conversation? Drop us a line, we’d love to discuss your next device.