Why our clients are often surprised at how much a flex arm costs

Share:

Medical device manufacturers find real value in what we bring to the table. Why? Well, it starts with the average price of an assembly, which costs between $30 – $100 per unit at its most basic level. Why such a range? The lower end will be a single continuous gooseneck with basic threaded fittings and covering materials. The higher end tends to include more sophisticated CNC fittings, higher quality covering materials, greater assembly time to install internal cabling or more exacting quality requirements.

But to really answer this question, we’re going to have to take a wider look at the marketplace, our role within it, and how we came to develop parts in the medical space.

Medical device components are often expensive

Medical devices have to meet high standards before they are ready for the marketplace. After all, a hospital is the last place you want a device to have problems. Devices that deliver safe and effective treatments and enhance user experiences require months or years of development. As a supplier to medical device OEMs we know there is always a desire to meet performance and user experience expectations, while keeping costs as low as possible.

Technology advancement has allowed the flex arm to become a better option.

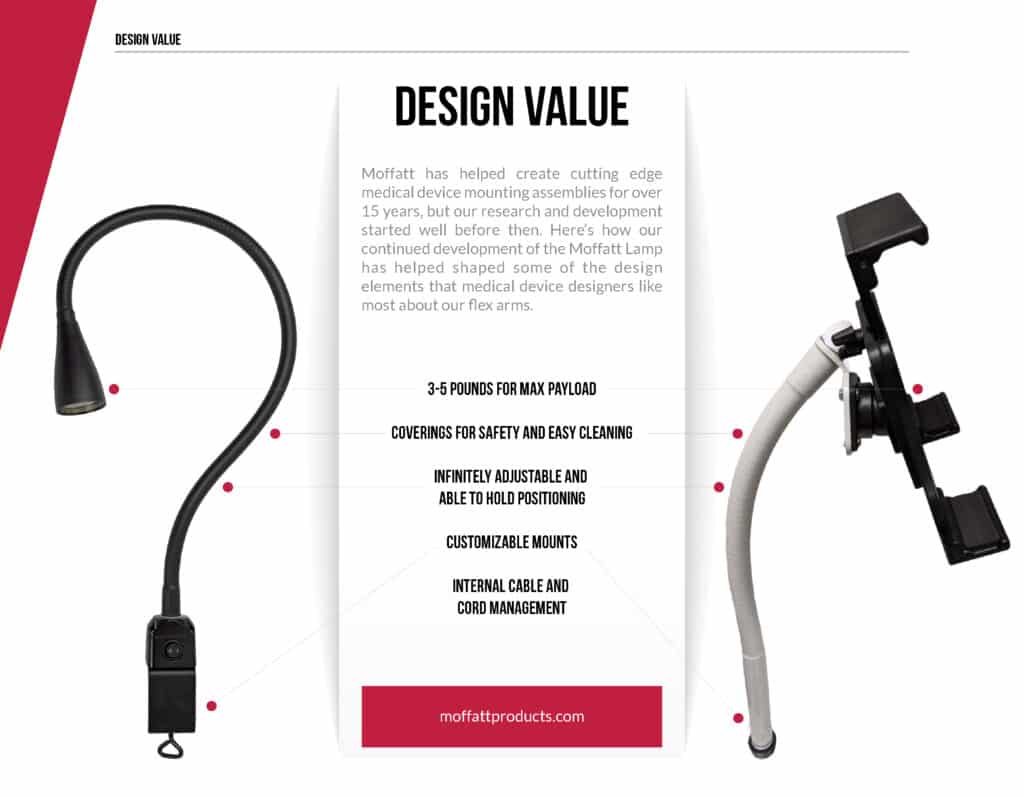

We entered the medical device space more than fifteen years ago, supplying mounting assemblies for LED exam lights and positioning arms for line and cable management. The standard weight capacity for one of our flex arms is between 3-5 pounds, which used to preclude it from other options that could support more weight. As electronics are now smaller and faster, devices too are lighter weight.

These days there are all kinds of devices that we can support. From lights to screens to all sorts of diagnostic equipment, the advancement of technology has created a real opportunity for flex arms in the medical device community.

Rapid prototyping has allowed more people to find flex arm solutions

Are you curious about a flex arm in your next medical device? Well, instead of talking in hypotheticals, we offer rapid prototyping. In our experience as engineers, it’s always better when you can get your hands on the real product. Our manufacturing processes allow us to quickly create new combinations with standard components, so you can evaluate both design concept and manufacturing quality at the beginning.

Our real value is in customization and communication

One of the main reasons that customers reach out to us is because they understand the value of working with Moffatt. We work step by step with engineers and product managers to understand the needs of the product and users, and select components which will deliver the best performance for the end users. We are not a flex arm vending machine with the lowest cost pricing, but rather a design partner who will feel more like an extension of your engineering department.

In short, customers are so surprised about our price because of the value they get when they work with us. Flex arms are a unique product. You want someone who has done it before and has an established solution. The parts happen to be much more affordable than alternative mounting solutions on the market today, and it doesn’t take long to find out if it is a good fit for your next project.