How to Get the Best Out of Your Flex Arm Device: Cost and Flexibility

Share:

Flex arms are like life: a series of tradeoffs and knowing where to find value. You can get the fast car, but the insurance will be through the roof (as will your spouse’s blood pressure). You can have a giant lawn, but someone is going to have to mow it.

Flex arms are like this too. You want a strong arm to support your payload, but you’re going to need arm adjustments to be as easy as possible. Just because there’s a trade-off though, doesn’t mean you should settle for an arm that doesn’t work the way you want it to. Here are a few tricks to ensure flexibility without sacrificing the other items on our Engineer’s Checklist.

3 Tips For More Flexibility in Your Flex Arms

For the purposes of this section, we’ve broken your options down into three different flex arm types, single section arms, multi-section arms, and brass triangular wire flex arms. While there are nearly limitless applications (check out one of our new favorites, SproutsIO) for flex arms, many problems can be solved by looking at one of these three flex arm types.

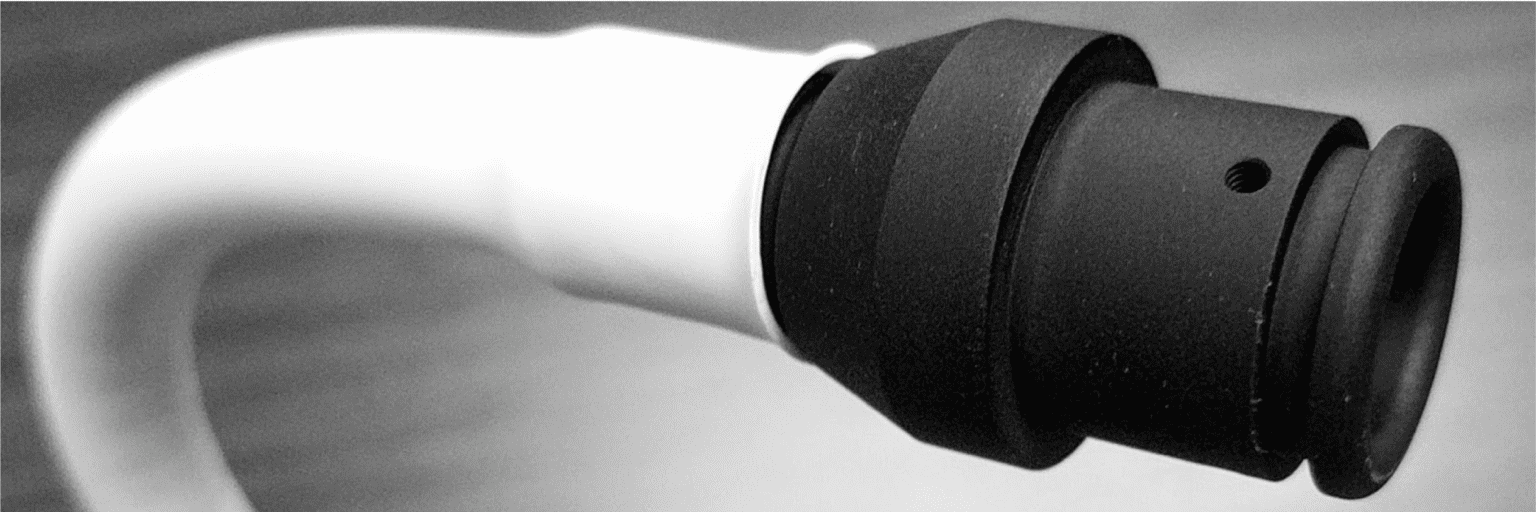

Flex arm option #1: Single Section Arms

There are a few tricks of the trade flex arm providers can use to make sure that you keep the strength required of your flex arm while preserving much-needed flexibility. This can include employing stiffeners or reinforcing agents that retain the arm’s pliancy. These treatments often come into play after your provider knows the prerequisites covered in the previous section. Items like positions your product and flex arm will see, center of gravity, etc.

Flex arm option #2: Multi-section Arms

Sometimes a sweet spot can be reached with some of the implementations listed above, but sometimes even that won’t get us exactly where we need to be. In those cases, we recommend designers employ multi-section arms. It allows arms with softer upper sections (for maximized flexibility) without sacrificing the strength needed for load capacity by the lower arm at the mounting base.

Flex arm option #3: Brass Triangular Wire Flex Arms

In the end, you’re looking for smooth, fluid adjustability that won’t pop or creak when you use it. While that isn’t expressly a flexibility issue, it’s something that we run into as a common need quite often. In some instances, like for medical or other high-end applications, designers need those arms to be totally silent.

In that case, we recommend using brass triangular wires. They’re the ultimate in performance and ensure that your device will have supreme flexibility without sacrificing its strength or reliability. It may be a bit pricier than other options, but if it’s a requirement — it can, and should, be brass.

How to Keep a Price Point Reasonable for Your Flex Arm

No matter how high our ideals are, the cost is always a crucial factor in production. That’s the world we live in. Having specific pricing goals is important, but those end results can be different than the reality of the situation. That can mean more expensive, but it doesn’t have to. We’ve actually had clients who are surprised — they have one idea of where a price point is going to be, but don’t realize that in some cases it’s less expensive than they thought. Here are some tips on how to accurately gauge where your price point will be — and how to keep costs down where you can.

Plan Ahead for Volume

Just a little more volume can go a long way. Sometimes it’s best to explore a stocking agreement or commit to blanket orders to obtain:

- shorter lead times

- reduced manufacturing costs

- more competitive pricing

Don’t be afraid to negotiate these terms to protect your supply chain from disruption!

Standard Pieces for Custom Designs

Often standard components will work well even in custom designs. It’s important to find a flex arm vendor that has a large array of components to choose from. They can keep costs down by buying in larger volumes for multiple customers. While your device is custom, it doesn’t mean that your components have to be.

Flex Arms May be the Cheapest Option

For the money, flex arms are often a less expensive option than a lot of their alternatives. A properly selected and designed flex arm can often replace more expensive support systems like counterbalanced arms. Integrating them into your designs can help keep that price point closer to where you need it to be.

Good Flex Arms are Worth More Than Cheap Ones

Buying a cheap flex arm might seem attractive in the beginning, but often there’s a huge hidden cost when they can’t perform or fail in the field. It’s hard to compare the value of something that works to something that doesn’t. We’ve spent literally decades studying, testing, documenting and sourcing the many combinations of diameters and wire strengths needed to offer an array of robust solutions. We sweat those details so that you can be confident your product will be well supported in the field.

Questions on what else we look for in a flex arm device design or how we can help?

Check out our free Ebook, The Engineer’s Checklist for Your Flex Arm Device today

_____________________

Working on a flex arm design? We are here for a no-pressure phone call. We’d love to hear more about what you are working on and give you ideas and prototypes to improve your decision-making process. Give us a call, we promise it will be worth your while.