What are the 5 Features that You Need in a Flexible Arm?

Share:

Although flexible arms have been around for a long time (we’ve been doing this since 1956!), the technology has certainly evolved. A lot of customers come to us and ask, what are my options when designing a product with a flexible arm? Naturally, that depends on what your needs and budget are, but we’ll cover the basics to think about when developing product positioning for your next design. No matter what you need in a flexible arm or what your budget is, chances are we’ll have a solution to whatever ails you (or your device).

1. Length

This comes down to the needs of the device — which basically boils down to length and strength. How long do we need those flexible arms to be? How much weight will they be bearing? Will they look cool? Just kidding on that last one. Just wanted to make sure you were still paying attention.

2. Strength

Think about which is more important to your product design — length or strength of the flexible arm? Depending on if you are developing a medical device or a task lamp, the hierarchy of needs with your product will differ. That’s why we work with designers and engineers to ask the right questions to create a simple solution for a complex problem. (If you want to see an example of our recent work check out First Healthcare Products iPad cart). While there may be a ton of different minutiae that goes into each and every one of our products, in the end, it boils down to length and strength.

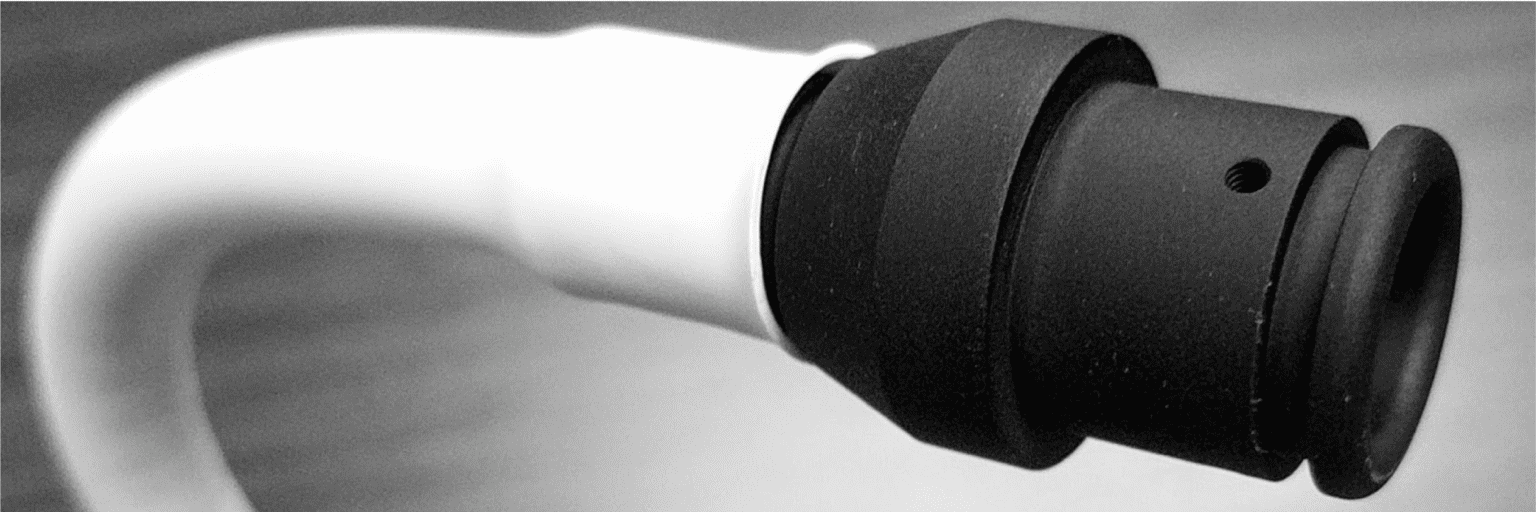

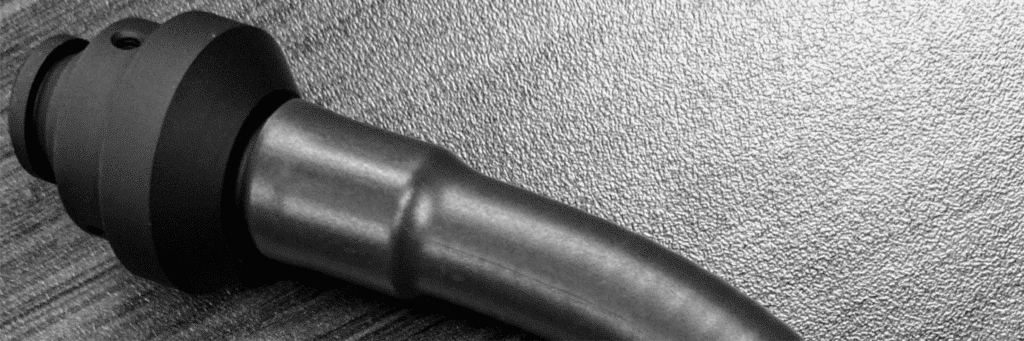

3. End Fittings

End fittings consist of basic threads, quick-disconnects, CNC fittings, die castings, or complete mounts. Those complete mounts could be things like magnets or c-clamps, but we’ve even had things like 3D printed connectors for prototypes or production.

Our end fitting materials include options like steel, stainless steel, aluminum, brass, or other material — depending on the needs of the flexible arm. Yes, all flexible arm questions typically stem from the length and strength question, but there can be other factors that lead us to recommend a specific material.

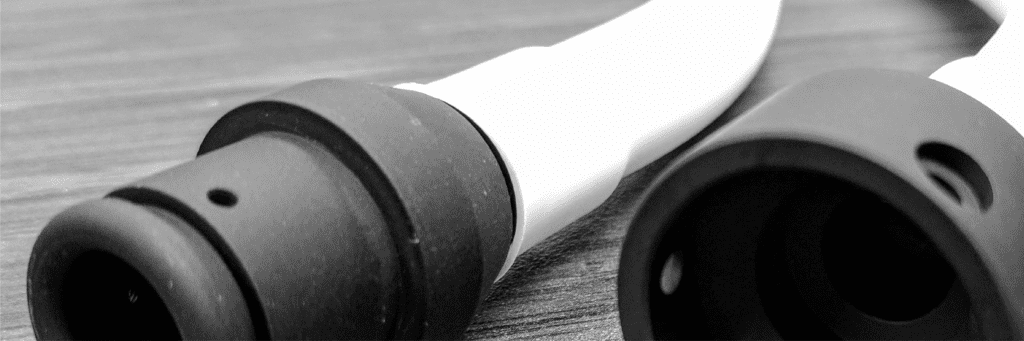

4. Number of Arms

If we start to think on a more complex scale, we get into things like dual or triple arms. This will certainly require a whole host of additional questions and assessing priorities, but as long as you have a partner dedicated to finding the solution, anything is possible.

5. Colors & Materials

There is a whole host of covering materials and colors for flexible arms. This is especially important to think about in relation to the other materials that make up the device. How durable does the material need to be? What kind of environment does it need to survive (and thrive) in? What are the temperature conditions like? Are there additional natural elements? How often will the flexible arm device be used?

That’s quite a list already, and I know what you’re going to ask: Is there more? More options, more possibilities? Oh yes, there’s more. For example, we didn’t even get into internal and external stiffeners and strain reliefs. We offer a wide variety of solutions to our customers, ranging from completely custom to a hybrid of ready-made and custom parts to off-the-shelf offerings. No matter what your needs or budget are, we will find you a solution.

If you’re on the edge of your seat, tickled by the possibilities for your next flexible arm device, then we’d love to hear from you. That’s the exact sort of person we love to work with. We offer no pressure calls with our team where we simply ask you a few questions and create a prototype. Seriously, we just love this stuff. Give us a call.